Wrt Cross Flow Cooling Towers Watco Group

Wrt Cross Flow Cooling Towers Watco Group Wrt series cross flow cooling towers are specially designed for air conditioning and industrial applications. we warrant the thermal performances and the maximum service life of our products. find the best cross flow cooling tower for your industries at unbeatable prices from the renowned company watco group. Field erected frp cooling towers. from our start in 1984, we have specialized in industrial cooling solutions with a product range for projects at all different levels of complexity. our field of expertise is in modular mechanical draft cooling towers utilizing frp (fiberglass reinforced plastics) structures.

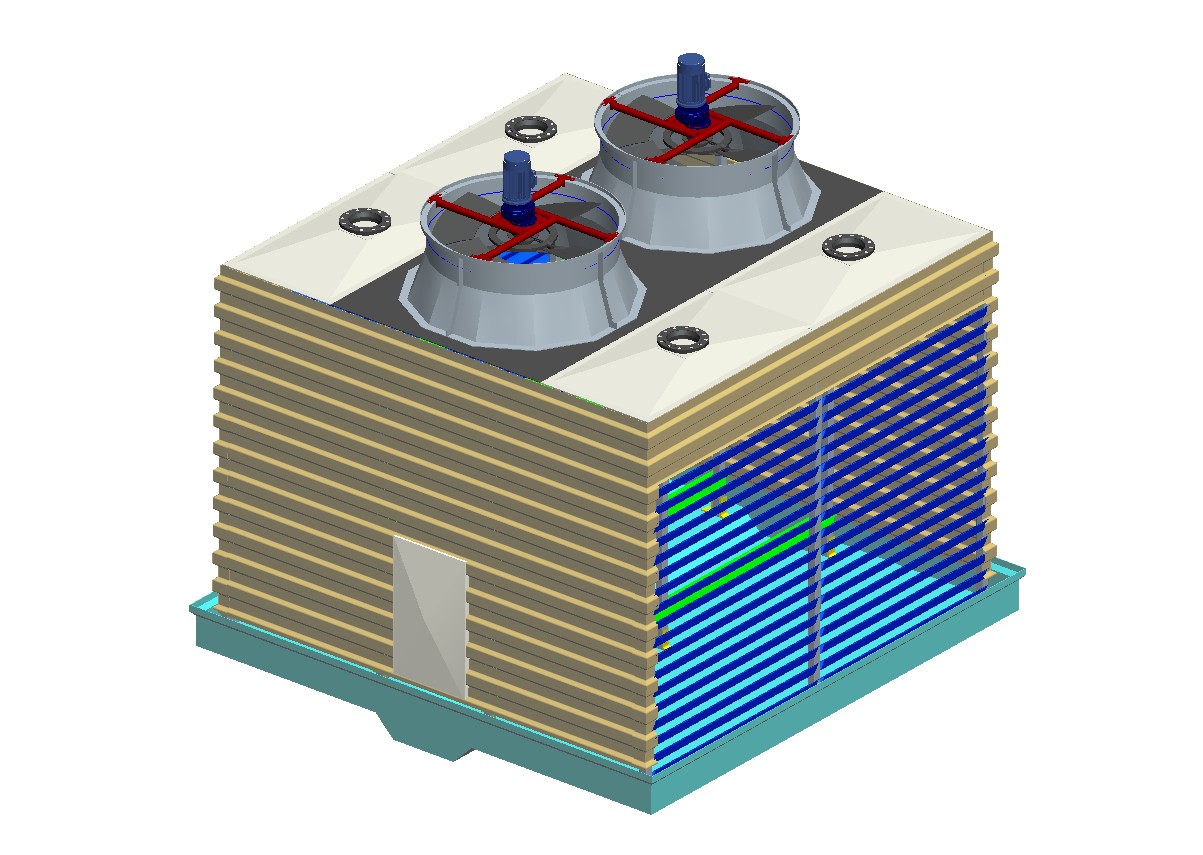

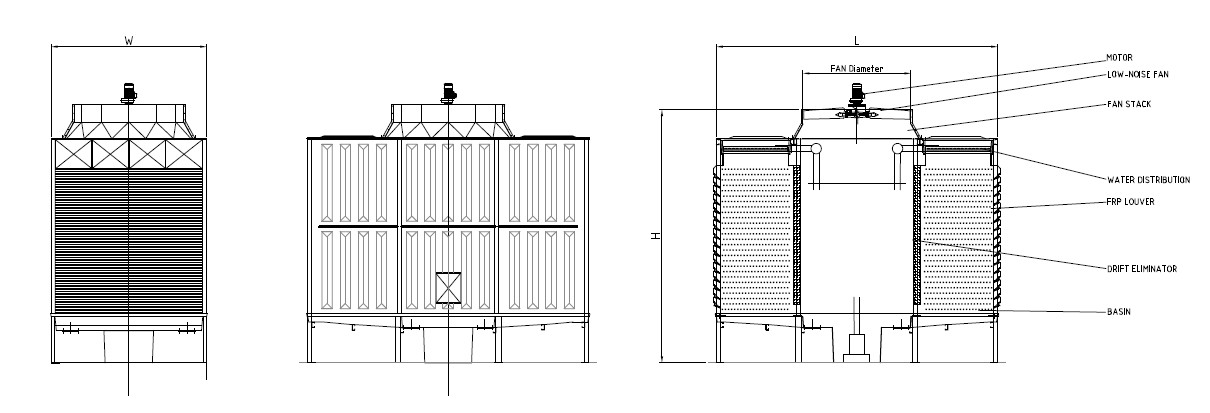

Wrt Cross Flow Cooling Towers Watco Group December 9, 2013 cooling tower wcn, cooling towers. the towers cool waste water effluent direct for further processing. scope of supply: 3 x 6 sets wcn special designed super low noise cooling towers in stainless steel aisi 316. centrafill non clogging type infill is used to handle the contaminated and ca rich water. Wacon wrt cross flow cooling towers by watco pte ltd. wrt cross flow cooling towers are the result of extensive research, development, and testing. the high performance, reliable and cost effective components, designed as state of the art technol. Especially designed for air conditioning and industrial applications, the wrt cooling towers are lightweight and extremely rigid structure. it is the result of extensive research, development, and. Smaller tower footprint; efficient air water contact through droplets formed by spraying; cannot use gravity flow for hot water distribution basin; hot water line needs to be pressurized thus increasing operational cost and noise compared to crossflow; forced draft: air is pushed into the cooling tower by a fan located at the base; efficient.

Wrt Cross Flow Cooling Towers Watco Group Especially designed for air conditioning and industrial applications, the wrt cooling towers are lightweight and extremely rigid structure. it is the result of extensive research, development, and. Smaller tower footprint; efficient air water contact through droplets formed by spraying; cannot use gravity flow for hot water distribution basin; hot water line needs to be pressurized thus increasing operational cost and noise compared to crossflow; forced draft: air is pushed into the cooling tower by a fan located at the base; efficient. This type of tower is an induced draft tower because the air passes over the heat exchanger before passing over the cooling tower fan. cross flow cooling tower cross section 3d model components. this 3d model shows all major components associated with a typical induced draft cross flow cooling tower, these include: fill (heat exchanger) spray. The fxt cooling tower delivers efficient performance and has the lowest operating costs for small scale projects. standard design features satisfy today’s environmental concerns, minimize installation costs, maximize operating reliability, and simplify maintenance requirements. thermal capacity: 58 257 tons 1. flow rate: up to 1,155 usgpm 1.

Dsm Genk Process Water Cooling Tower Watco Group This type of tower is an induced draft tower because the air passes over the heat exchanger before passing over the cooling tower fan. cross flow cooling tower cross section 3d model components. this 3d model shows all major components associated with a typical induced draft cross flow cooling tower, these include: fill (heat exchanger) spray. The fxt cooling tower delivers efficient performance and has the lowest operating costs for small scale projects. standard design features satisfy today’s environmental concerns, minimize installation costs, maximize operating reliability, and simplify maintenance requirements. thermal capacity: 58 257 tons 1. flow rate: up to 1,155 usgpm 1.

Leading Cooling Technology Engineers Watco Group

Comments are closed.