Understanding The 6 0 Powerstroke Oil Cooler System A Complete Diag

Understanding The 6 0 Powerstroke Oil Cooler System A C An oil cooler is a critical component in the 6.0 powerstroke engine system. it plays a vital role in maintaining optimal engine performance and preventing overheating, which can lead to engine damage. the 6.0 powerstroke engine produces a significant amount of heat, especially under heavy load or towing conditions. Advice input needed. i have a 2004 6.0 with 170,000 miles on it. i noticed that i had some oil leaking on my driveway. upon further inspection i found that the oil was coming from the top and rolling down the bell housing. put dye inside the oil, ran it for a week and ran a uv light confirmed the oil was leaking out from the oil cooler.

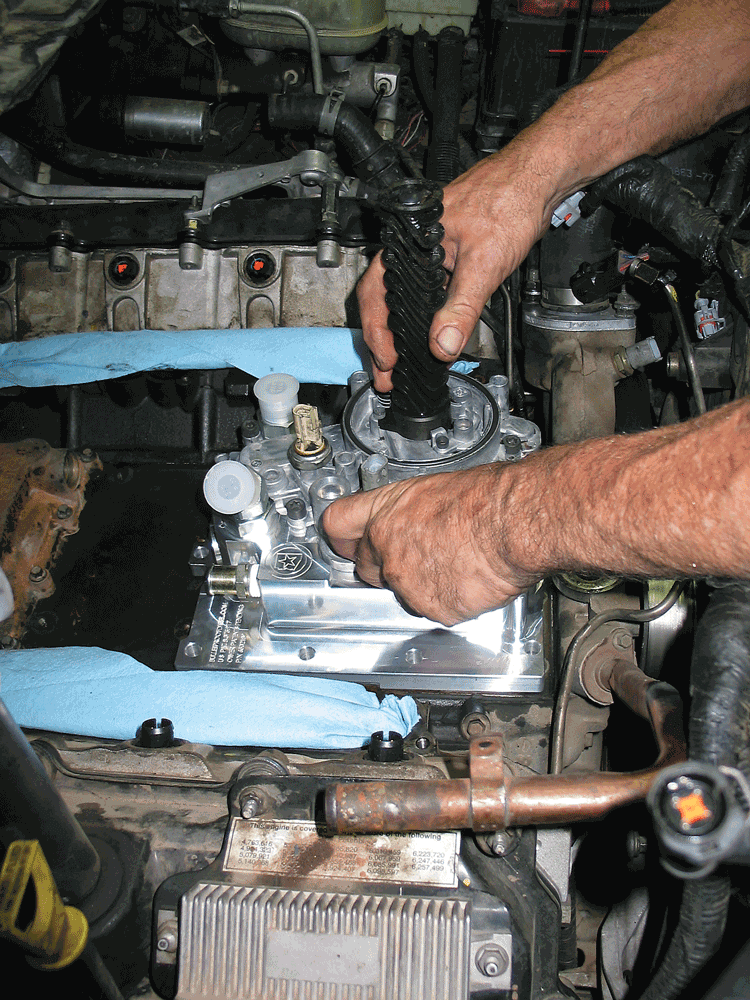

Understanding The 6 0 Powerstroke Oil Cooler System A C The high pressure (hp) oil system that used for the fuel injection system on the ford 6.0l engines can be very tricky and time consuming to diagnose when problems arise. it is important to have an understanding on how the system works to be able to accurately diagnose and repair it. here is a little background on this system before we begin. 124 posts · joined 2011. #1 · jul 9, 2018. truck in question: 2008 6.4l 88,000 miles, egr and dpf deleted. i am fearing i have very early signs of the oil cooler failing. i want to try and nip this early to try and avoid a costly replacement. i have read an enormous amount on the many psd forums and watched numerous videos. Buy 6.0 powerstroke high pressure oil system parts monitor the icp and ipr while cranking. if icp is .4v to .5v (200 psi) and ipr is 85%, it is possibly a stuck ipr. the system will build 200 psi even if the ipr is open. make sure that oil pressure registers on the dash gauge while cranking, if not you may not have enough low oil pressure. oregon. Some engines, like the 6.0 power stroke, take this a step further by adding a cooler to extract heat directly from the oil. while the 6.0’s oil cooler is effective, it also has a history of pattern failures. these problems can be addressed by installing a 6.0 oil cooler relocation kit or a complete 6.0 power stroke oil cooler upgrade. common.

6 0 Power Stroke Oil Cooler Upgrade Diesel World Buy 6.0 powerstroke high pressure oil system parts monitor the icp and ipr while cranking. if icp is .4v to .5v (200 psi) and ipr is 85%, it is possibly a stuck ipr. the system will build 200 psi even if the ipr is open. make sure that oil pressure registers on the dash gauge while cranking, if not you may not have enough low oil pressure. oregon. Some engines, like the 6.0 power stroke, take this a step further by adding a cooler to extract heat directly from the oil. while the 6.0’s oil cooler is effective, it also has a history of pattern failures. these problems can be addressed by installing a 6.0 oil cooler relocation kit or a complete 6.0 power stroke oil cooler upgrade. common. Head studs provide inadequate clamping force so blown head gaskets are common. other 6.0l powerstroke problems include hpop failure, injector stiction, ficm failure, and clogging oil coolers. fortunately, once these problems are addressed, the trucks are much more reliable. some of these problems can be avoided. You really should pre charge the turbo with oil. remove the standpipe in the oil filter housing and pour a quart of oil down the hole. crank at first (say a half dozen 20 second cranks with a minute wait in between) with the starter solenoid wire jumpered to the passenger positive terminal. do this without the key turned to on.

Comments are closed.