Evapco Cooling Tower Piping Diagram

Evapco Cooling Tower Piping Diagram Evapco blct dry cooling, inc. 1011 us highway 22 west bridgewater, nj 08807 usa phone: 1 908 379 2665 e mail: info@evapco blct evapco blct dry cooling, inc. 7991 shaffer parkway littleton, co 80127 usa phone: 1 908 379 2665 e mail: info@evapco blct spare parts phone: 908 895 3236 spare parts e mail: spares@evapco blct. Evapco promotional merchandise. understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower.

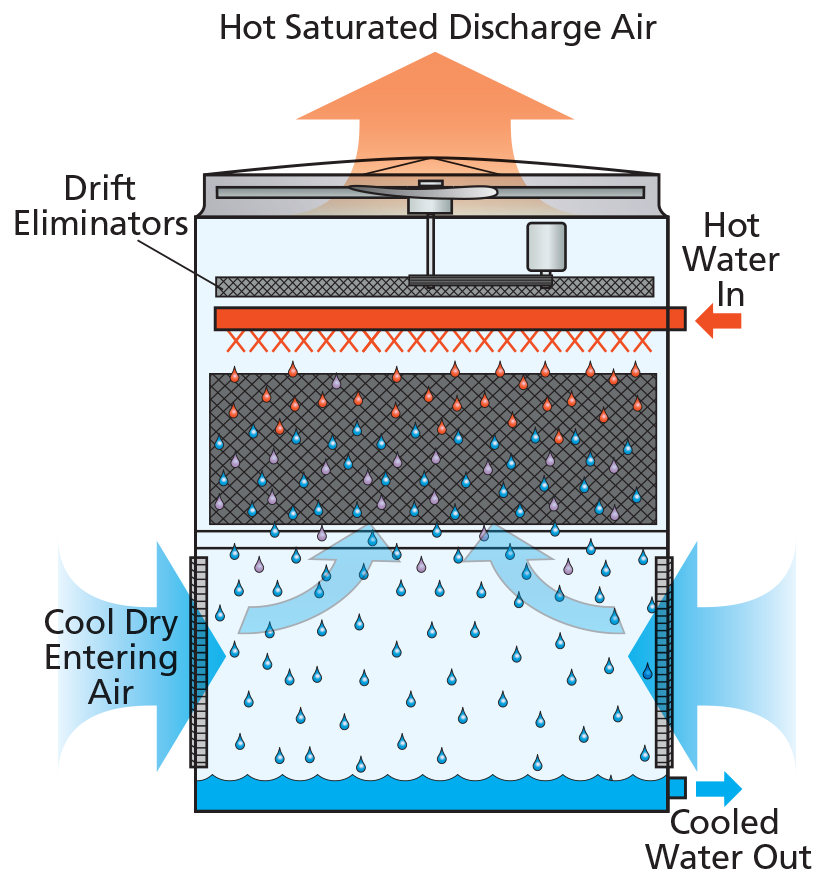

Evapco Cooling Tower Diagram For more information on cooling tower layout, please refer to evapco equipment layout bulletin 311. cooling tower piping: when designing a cooling tower system for free cooling applications, several piping details should be considered to ensure proper winter operation of the unit. 5 at uat 1,2 m wide units. 6 at uat 2,4 and 2,6 m wide cells. download this manual. operation and maintenance instructions. for evapco induced draft and forced draft cooling towers. at. evapco, inc. (world headquarters) p.o. box 1300, westminster, maryland 21158 usa. evapco europe. bvba. Evapco recommends that the cooling tower bypass be installed in the condenser water piping system. page 22 it is very important to maintain close control of the cooling tower during winter operation. evapco recommends that an absolute minimum leaving water temperature of 42° f must be maintained; obviously, the higher the water temperature. Evapco evaporative cooling units use either a t.e.a.o. (totally enclosed air over) or a t.e.f.c. (totally enclosed fan cooled) fan motor. these motors are built to “cooling tower duty” specifi cations. they are supplied with permanently lubricated bearings and special moisture protection on the bearings, shaft and windings.

Evapco Cooling Tower Manual Evapco recommends that the cooling tower bypass be installed in the condenser water piping system. page 22 it is very important to maintain close control of the cooling tower during winter operation. evapco recommends that an absolute minimum leaving water temperature of 42° f must be maintained; obviously, the higher the water temperature. Evapco evaporative cooling units use either a t.e.a.o. (totally enclosed air over) or a t.e.f.c. (totally enclosed fan cooled) fan motor. these motors are built to “cooling tower duty” specifi cations. they are supplied with permanently lubricated bearings and special moisture protection on the bearings, shaft and windings. Evapco west madera, ca usa 559 673 2207 p contact@evapcowest evapco iowa lake view, ia usa 712 657 3223 p evapco iowa sales & engineering medford, mn usa 507 446 8005 p evapcomn@evapcomn evapco newton newton, il usa 618 783 3433 p evapcomw@evapcomw evapcold greenup, il usa 217 923 3431 p evapcomw@evapcomw evapco blct dry cooling. October 12, 2018. understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and.

At Cooling Tower Evapco Australia Evapco west madera, ca usa 559 673 2207 p contact@evapcowest evapco iowa lake view, ia usa 712 657 3223 p evapco iowa sales & engineering medford, mn usa 507 446 8005 p evapcomn@evapcomn evapco newton newton, il usa 618 783 3433 p evapcomw@evapcomw evapcold greenup, il usa 217 923 3431 p evapcomw@evapcomw evapco blct dry cooling. October 12, 2018. understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and.

Cooling Tower Piping Diagram

Comments are closed.