Electrostatic Fluidization Bed For Powder Coating

Fluidized Bed Powder Coating Plant Youtube Rector: with fluid bed coating, the part has to be preheated, immersed in the coating and then flowed out. long: electrostatically assisted fluidized bed coating does not dip the part into the powder, it generates a cloud of charged particles (much like a conventional electrostatic gun) through which a heated or an unheated part passes. it. Fluidized bed powder coating is a coating process where finely ground powder particles are suspended in air, and a preheated part is dipped into the powder bath. the melted particles fuse to the object, providing a consistent, even finish on metal parts. this type of powder coating is ideal for parts that need a thick, even layer but without a.

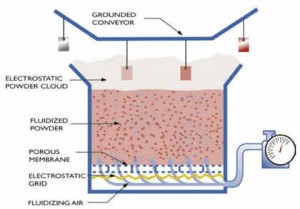

Electrostatic Fluidization Bed For Powder Coating Youtube The typical electrostatic spray powder coating setup can be expensive, though, and not necessarily suitable for every workpiece. enter the fluidized bed powder coating chamber, perfect for limited. The powder coach’s playbook: mastering the art of powder coating. valu line series powder coating equipment. the importance of transfer efficiency in detail. powder coating mdf the basics. powder coating metal repair filler – lab metal and hi temp lab metal. how to get started powder coating – the basics. the guide to custom matched touch. The fluidized bed powder coating applicator. the fluidized bed powder applicator is a specially constructed tank that is filled with dry powder in its upper region with an open plenum in the lower region, and a permeable membrane that separates the upper tank from the lower (figure 1). air is supplied to the lower plenum and allowed to diffuse. Moving the part while in the fluid bed helps to displace trapped air allowing the coating to reach these recessed areas. long— large areas of flat, horizontal surfaces need to have the excess powder removed as it comes out of the fluid bed coater. this can be accomplished by shaking the part, tilting the part so the powder falls off, or even.

Electrostatic Fluidized Bed Powder Coating Powder Coating The fluidized bed powder coating applicator. the fluidized bed powder applicator is a specially constructed tank that is filled with dry powder in its upper region with an open plenum in the lower region, and a permeable membrane that separates the upper tank from the lower (figure 1). air is supplied to the lower plenum and allowed to diffuse. Moving the part while in the fluid bed helps to displace trapped air allowing the coating to reach these recessed areas. long— large areas of flat, horizontal surfaces need to have the excess powder removed as it comes out of the fluid bed coater. this can be accomplished by shaking the part, tilting the part so the powder falls off, or even. Step 1: substrate preparation the first step in the fluidized bed powder coating process is substrate preparation. this involves cleaning the substrate to remove any dirt, grease or other contaminants that may prevent the powder from adhering properly. this step is critical to the success of the process, as any contaminants on the substrate can. The essence of fluidized bed powder coating lies in the principle of fluidization, which involves suspending fine powder particles in a stream of air. this is achieved by passing a controlled flow of compressed air through a porous plate at the bottom of a coating chamber, creating a fluid like state where the powder particles behave as if they.

Comments are closed.