Cooling Tower Process Flow Diagram I Force Draft Cooling Tower

How Cooling Towers Work Diagram Pictures Principles Sara Cooling ①why edrawmax to draw pid? find in: bit.ly 345zcq9②edrawmax free download: bit.ly 3qqluce③choose a template and get started now! click: https. 7. how cross flow cooling towers work 8. how counter flow cooling towers work 9. how forced draft & induced draft cooling towers work 10. how natural draft cooling towers work 11. factory assembled cooling towers (fap) 12. field erected cooling towers (fep) 13. how are cooling towers relate to atmospheric vortex engines? 14. cooling tower parts.

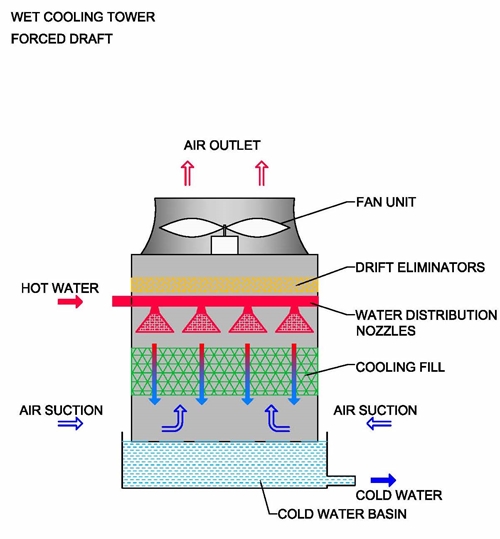

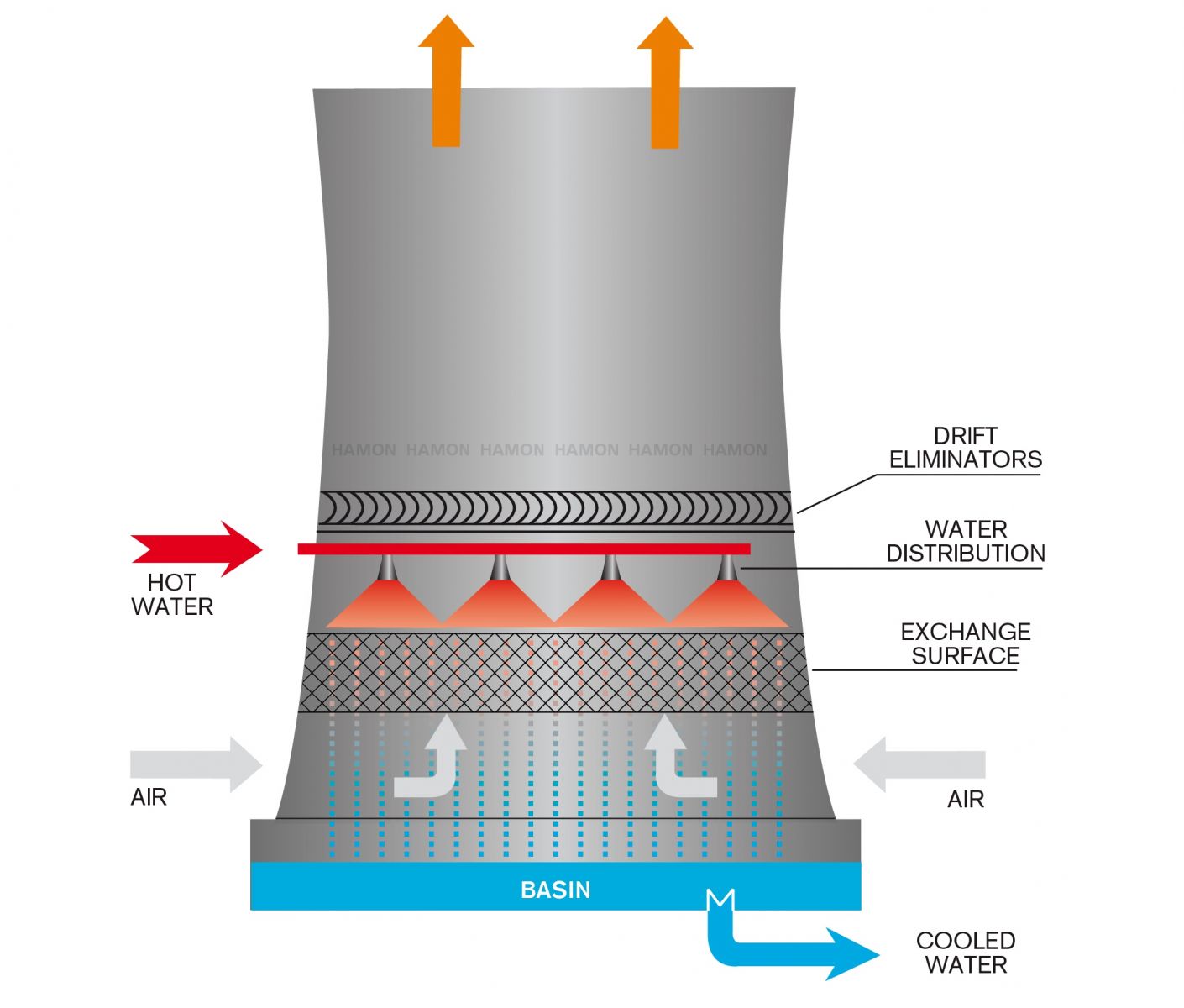

Do You Know What A Forced Draft Cooling Tower Is Cooling tower spouts are managed to diffuse the water over the “fill media,” that reduces the flow of water and reveals the maximum volume of water covering area desirable for the safest air water connection. the water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical. A cooling tower flow diagram helps visualise the complex system of the tower and its components. the diagram illustrates the flow of water and air through the tower, as well as the different stages of the cooling process. the cooling tower flow diagram typically begins with the entry of hot water from the industrial process into the tower. The forced draft cooling tower diagram provides a visual representation of how this type of tower operates. it typically includes various components such as the fan, motor, drive, inlet louvers, fill material, water distribution system, and drift eliminator. each component plays a crucial role in the cooling tower’s overall performance. A forced draft cooling tower is a type of mechanical draft cooling tower that employs mechanical fans positioned at the air inlet to actively force air through the tower. this design enhances heat exchange efficiency and distinguishes it from induced draft and natural draft cooling towers.

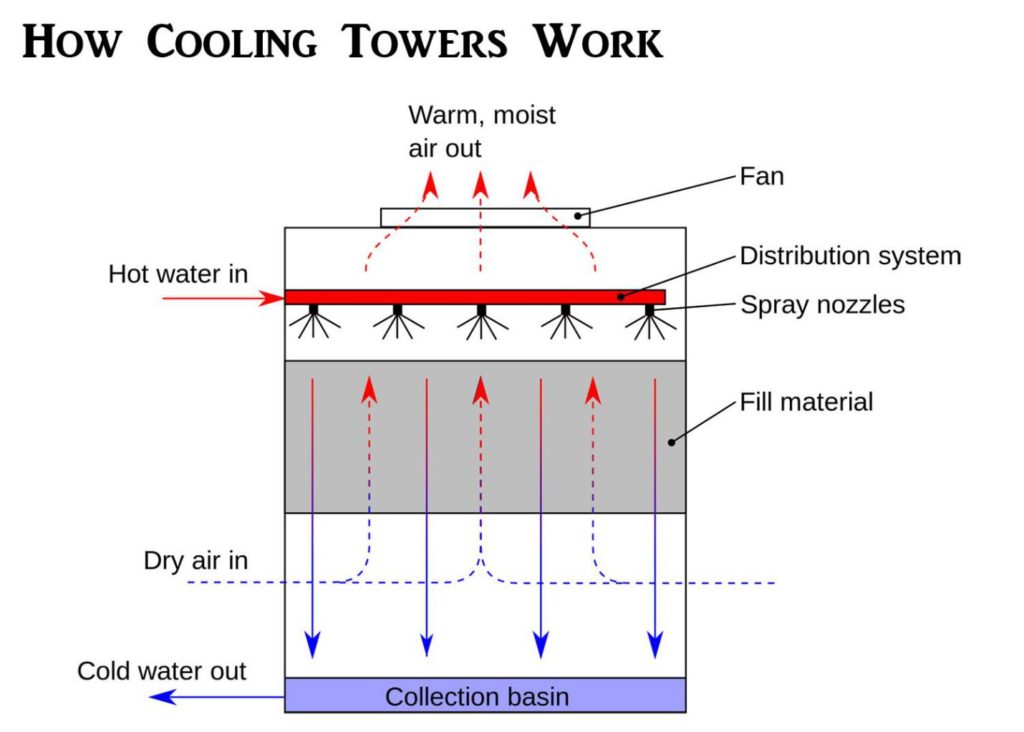

Induced Draft Cooling Tower Introduction And Types The forced draft cooling tower diagram provides a visual representation of how this type of tower operates. it typically includes various components such as the fan, motor, drive, inlet louvers, fill material, water distribution system, and drift eliminator. each component plays a crucial role in the cooling tower’s overall performance. A forced draft cooling tower is a type of mechanical draft cooling tower that employs mechanical fans positioned at the air inlet to actively force air through the tower. this design enhances heat exchange efficiency and distinguishes it from induced draft and natural draft cooling towers. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. during this process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower.

How Cooling Towers Work Diagram Pictures Principles Sara Cooling The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. Cooling towers are a special type of heat exchanger that allows water and air to come in contact with each other to lower the temperature of the hot water. during this process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower.

Comments are closed.